Compression fittings typically provide the best combination of durability and reparability. There are three main types of power cable terminations: compression, set screw and crimped. Routinely check these connections before problems arise in order to avoid compounded problems down the road. These include: the connection between the power source and the gun’s power cable plug the fittings and connections between the gun’s power cable, neck, diffuser, contact tip and welding wire and the connections between the work lead, welding table and power source. The mechanical connections between the welding components account for most interruptions in conductivity. Routinely checking the mechanical connections between the components can avoid problems before they arise.īeing able to correctly identify and troubleshoot excessive electrical resistance is critical to reducing the equipment and rework costs. Accurate TroubleshootingĪs seen in this schematic, there are many areas for interruptions in conductivity to occur. This increased voltage causes the popping and sputtering that leads to poor and inconsistent weld quality. When the power source senses the reduced current at the arc, it sends a surge of voltage in order to overcome the restricted current flow. These problems occur because resistance in the circuit reduces the amount of current that can flow to the welding arc. This includes a sputtering or erratic arc, inconsistent weld appearance and frequent contact tip burn-back. This results in increasingly poor welding performance.Įxcessive resistance anywhere along the circuit can result in a wide range of problems. As the contact tip absorbs the heat from the arc, it loses its ability to transfer the current to the wire. This is why high heat welding processes, such as with metal-cored wire, demand that the contact tip be recessed as far from the welding arc as practicable. Interestingly, heat itself is a source of resistance. Heat causes plastic and metal components to expand and to contract when cooled, creating mechanical stress that can lead to premature equipment failure. The surrounding components absorb the heat. When resistance prevents the electrons from continuing along the circuit, they convert their energy to heat. Likewise, an area of electrical resistance, such as a worn out or dirty power pin connection, restricts electrical flow along the entire length of the circuit. Squeezing the hose in one spot reduces the amount of water that is able to flow from the hose. The water flowing through the hose is analogous to the electrical current in the circuit.

To understand exactly how conductivity impacts almost every aspect of your welding operation, it helps to think about the welding circuit like a garden hose. Excessive resistance along the circuit, however, can cause weld defects, reduce productivity and lead to premature equipment failure. There is still a very small amount of resistance inherent in the properties of the material, but it is not enough to interfere with the welding operation.

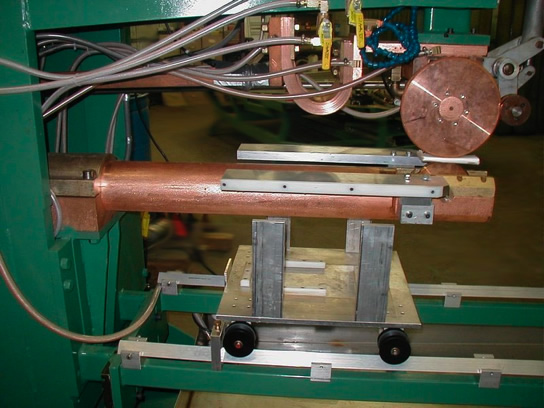

The copper used in welding equipment does a good job allowing the electrical current to flow.

Using copper, aluminum and other metals in welding equipment strike a good balance between cost and conductivity. Gold is one of the most conductive materials on earth, but its cost prevents its use in welding equipment. If the electrical current moves with very little resistance, the material is very conductive. Conductivity can also be referred to through its inverse: resistance, or the interference of electricity to flow freely along the circuit.

MOVEABLE SHUNT WELDER TROUBLESHOOTING HOW TO

Understanding the role conductivity plays in the welding operation and how to troubleshoot problems that can reduce downtime, rework and unnecessary equipment costs.Īll of these factors are ultimately affected by conductivity: the ability of the electrical current to flow along the welding circuit. Dura-Flux Self-Shielded Flux-Cored Gun with Replaceable Cable Liner.Dura-Flux Self-Shielded Flux-Cored Gun with Fixed Cable Liner.

0 kommentar(er)

0 kommentar(er)